The thing with lead-free solder is that it doesn't flow well below about 240C, but components can get damaged above about 255-260C (or, in some cases, 245C), and an oven only has a short time to get the temperature right. With this type of oven (basically, a grill), it's difficult to do that. Alternatives are a hotplate (requires a lot of skill/practice to get consistent results) or a convection/conveyer oven (if you have several thousands to spare or a company budget).

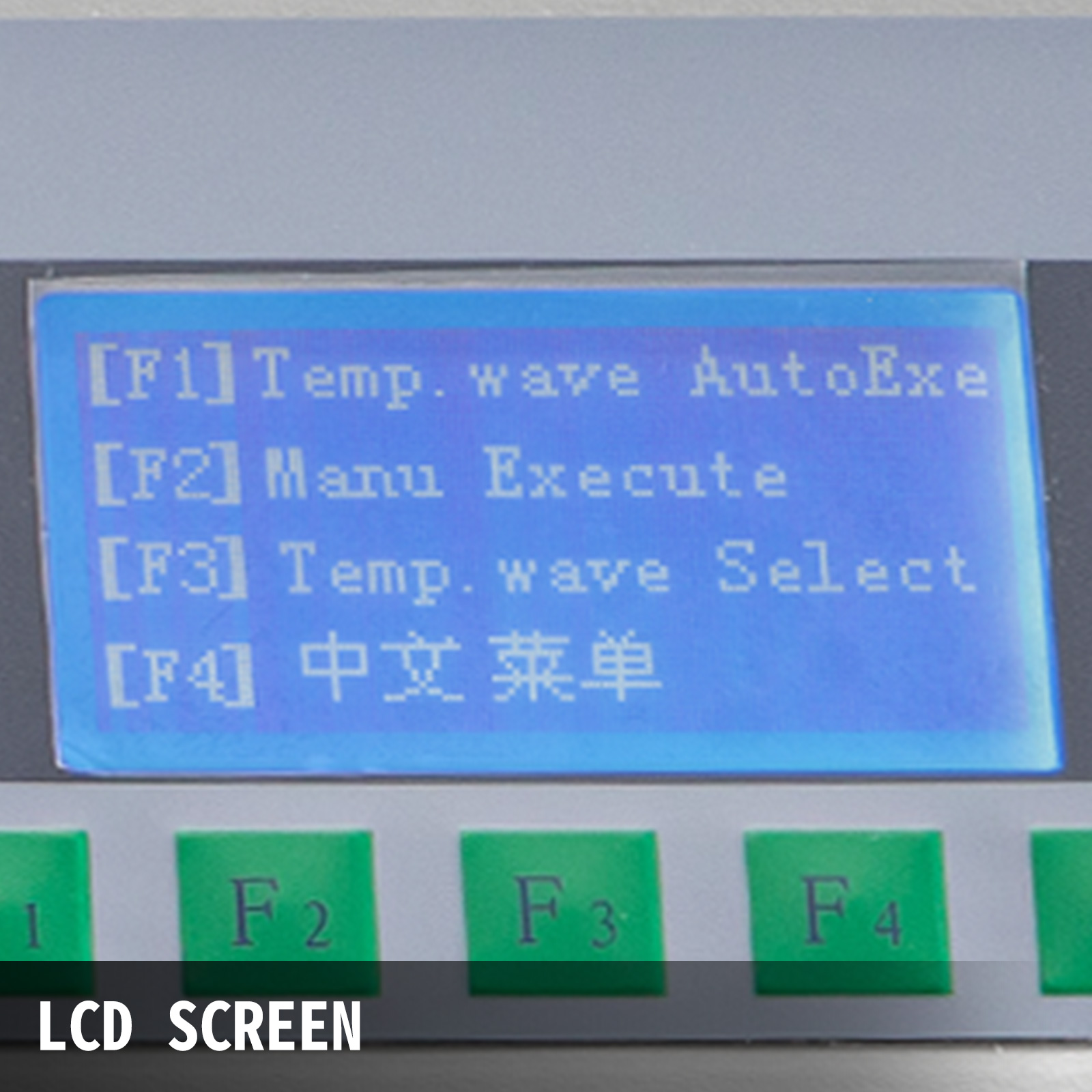

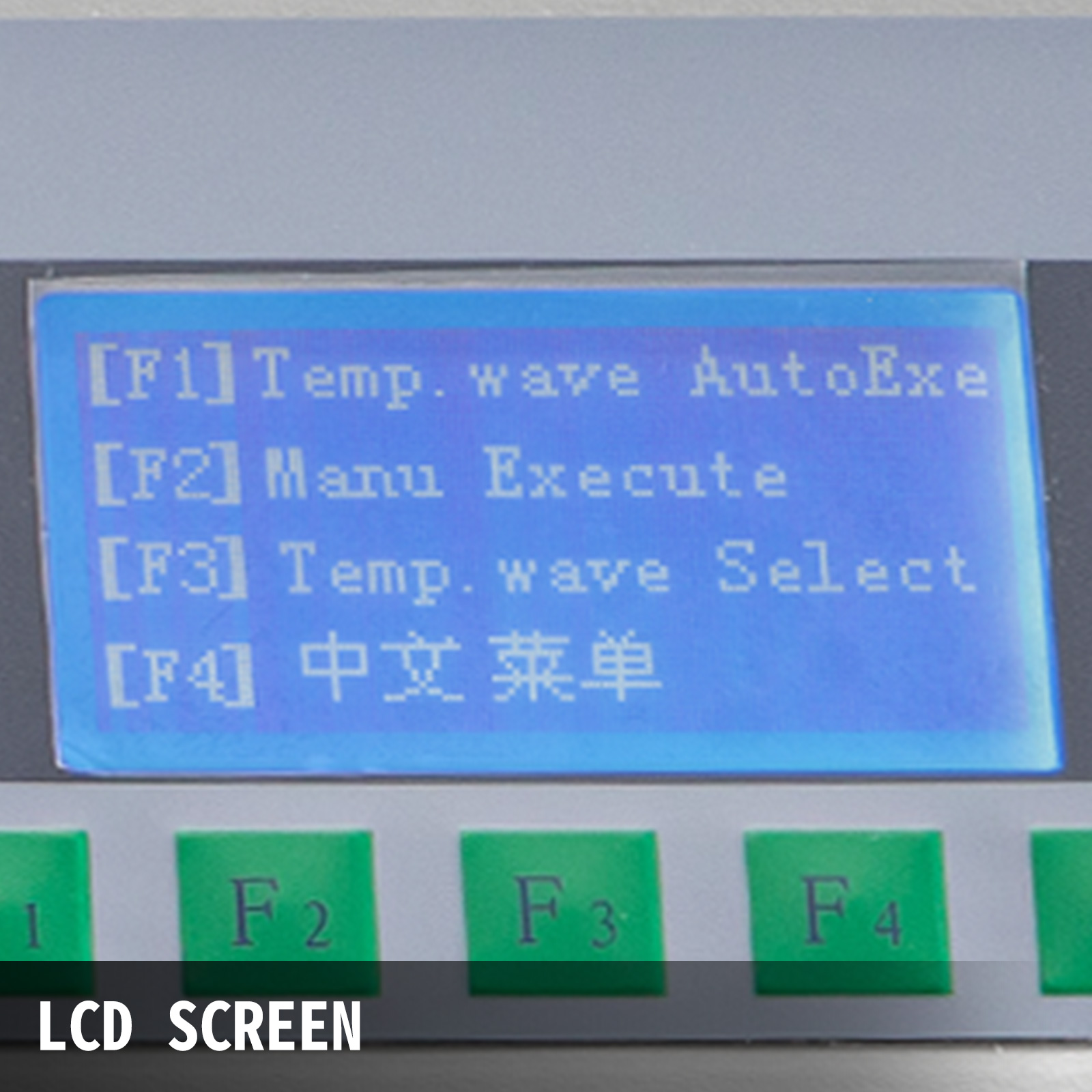

This oven comes with several preset temperature profiles, plus two you can set up yourself. I found the presets for lead-free got too hot, so spent quite a while setting up a good profile (thermocouples on an empty PCB plus trial and error). It's tricky, because the board temperature depends on things like board size, number and size of components, room temperature and, to some extent, randomness. I have not flashed the firmware or any other major modifications - that may help, and there are lots of YouTube videos about it.

A few tips: 1) open it up and remove the paint between the earth wire and the chassis (or at the very least, use it with an RCCB). 2) while it's open, change the masking tape for Kapton tape, including under the front of the insulation (it's easy to do). 3) connect a cheap aluminium foil pipe between the fan output and an open window. 4) to set a user profile, go to the profile, press for DEtails and then press (S). You tell it what temperature to be at for every 10 seconds. It seems to interpolate for the intervening times. Press (S) again to save. 5) raise the PCB above the metal shelf slightly so the shelf doesn't cool the board.

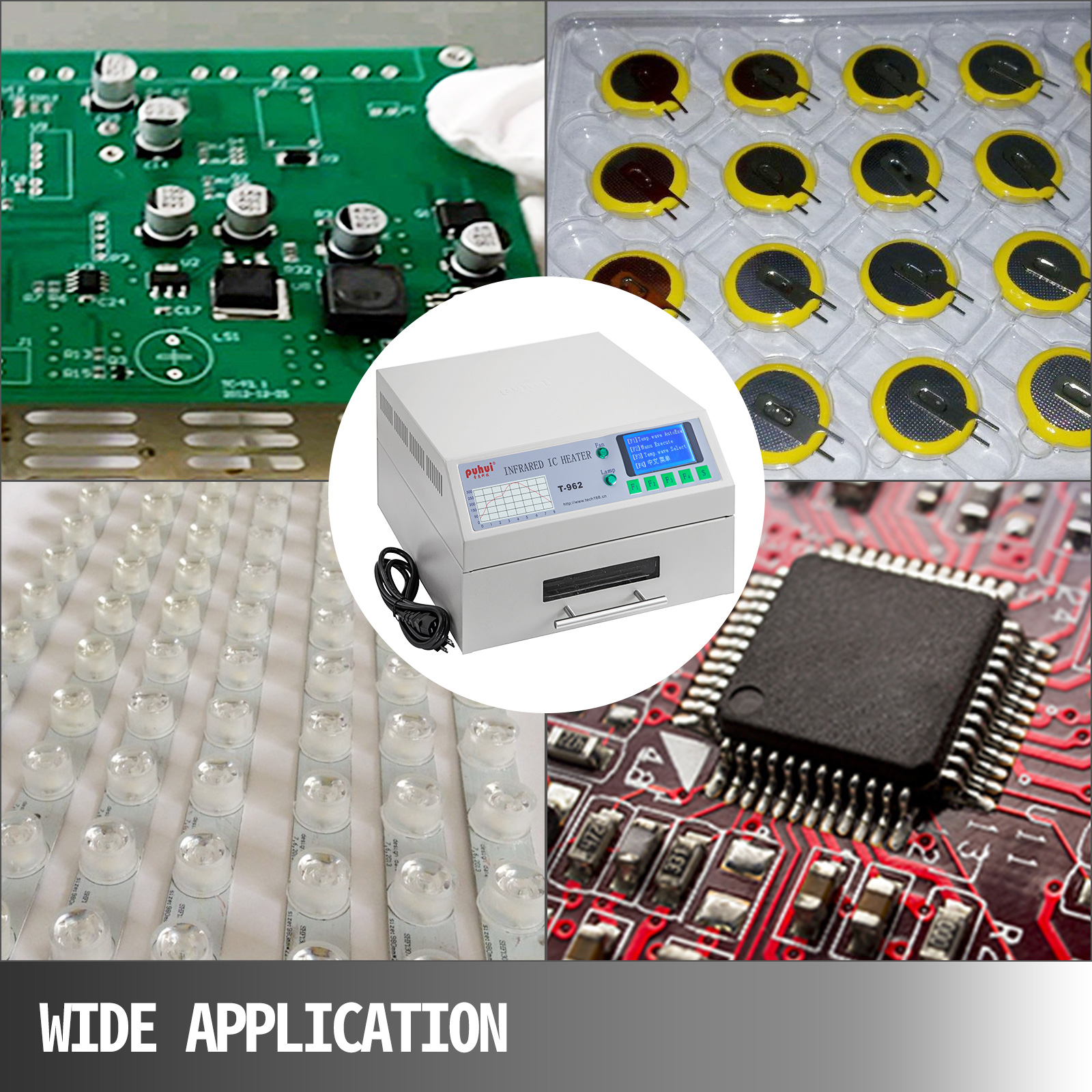

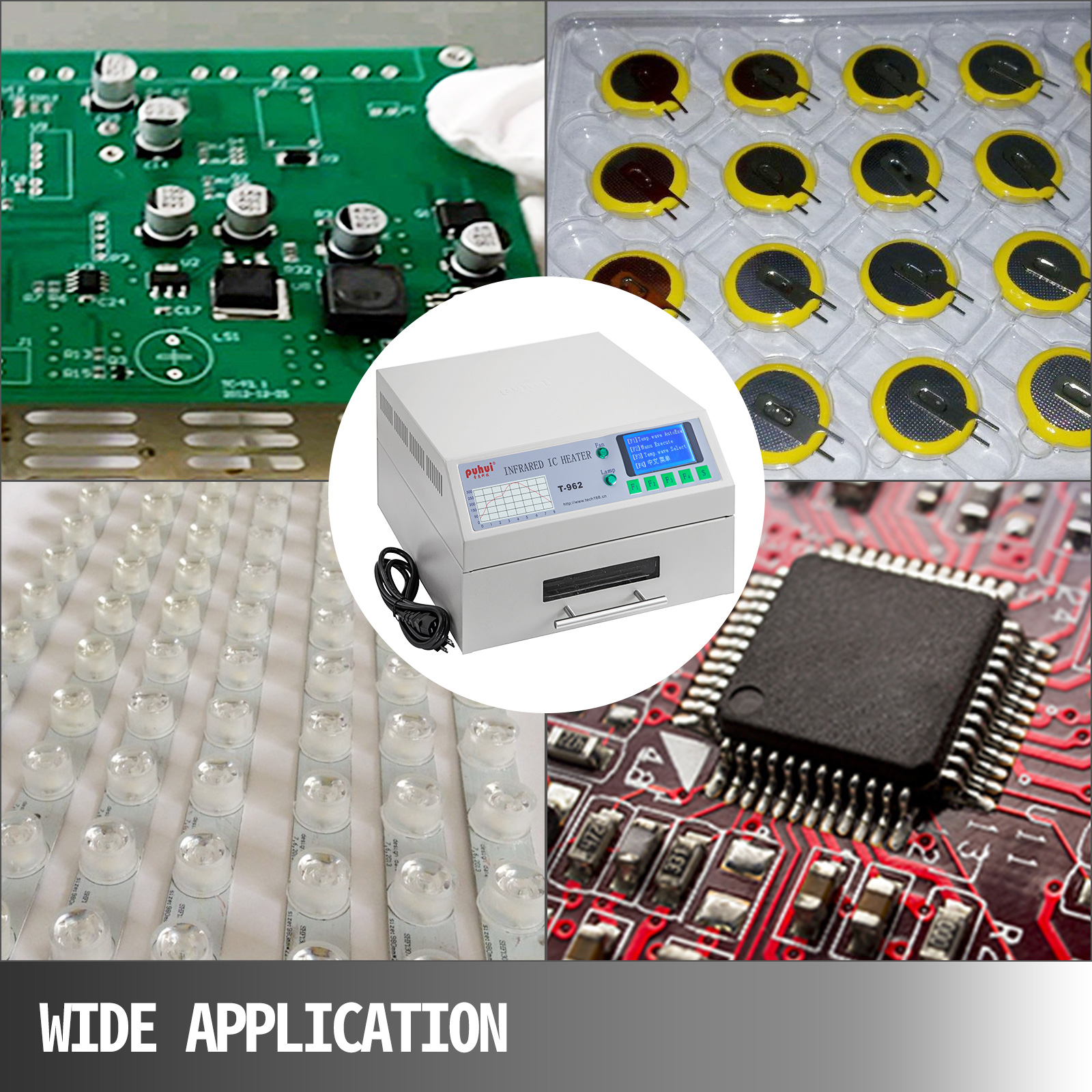

Overall, provided you are willing to mess around with it, and provided you are not trying to use it professionally or with extra-sensitive components, then you can get it to work pretty well and it's good value for money.