There is too much slop in the bearings, the upper roller moves up and down quite a bit. So the rollers move as the gears mesh and that gives a washboard surface in the metal being rolled. It comes out with sanding but is annoying and it really shouldn’t be hard to cut the rollers and the bearing blocks to a good fit.

I will probably take it apart and bore out the bearing blocks and press fit bronze sleeves.

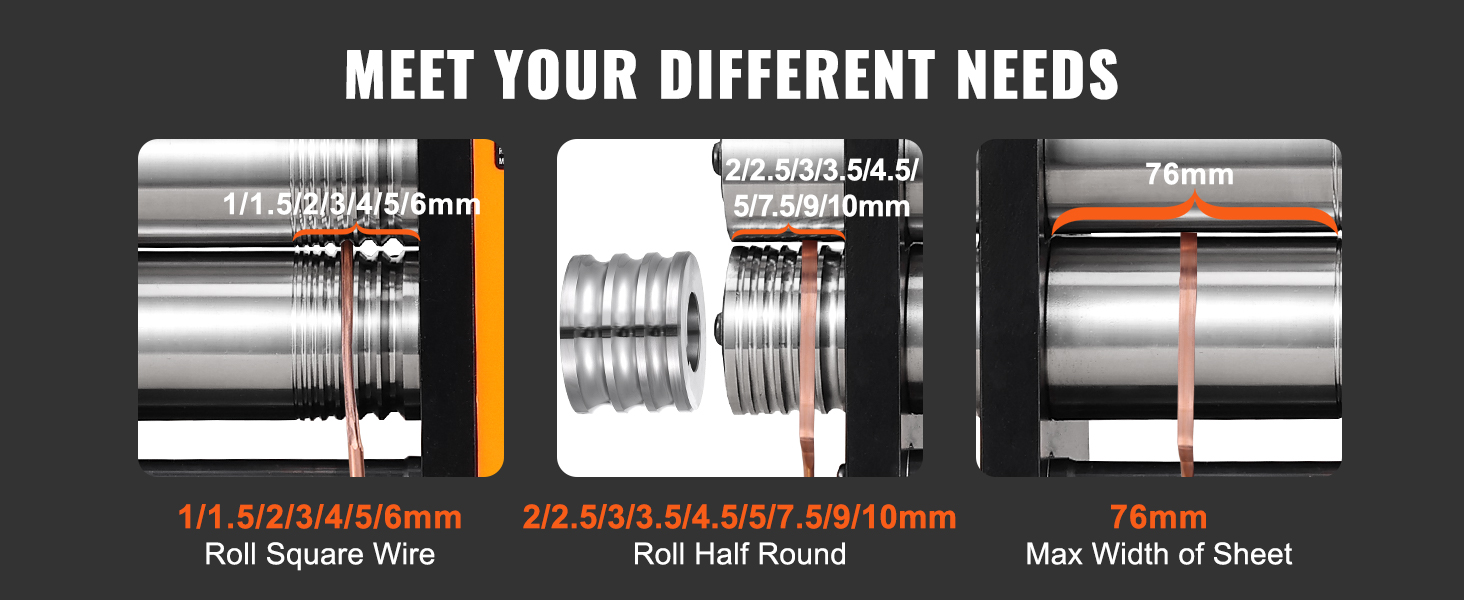

Second annoyance is that the square grooves don’t line up properly, so the wire ends up rhombus shaped.

That said it is dirt cheap and does roll metal. The gearing ratio makes it hard to turn if you take big bites, so smaller bites and more passes is where it’s at.