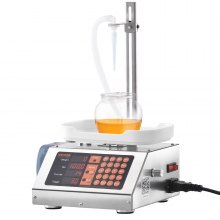

Our VEVOR cosmetic tube filling sealing machines provide high accuracy and precision with pneumatic fillers. They are suitable for both high viscosity liquids and pastes. Suitable for both high viscosity liquids, pneumatic filling, and acid delivery. The stainless steel structure resists corrosion, rust, and acids, guaranteeing longevity. Adjustable speed and volume meet your specific needs. Dual control modes allow you to choose between manual and automatic operation. Anti-drip nozzle saves more liquid during usage, making operations more efficient. With dual control modes, you can opt for your precise needs. The anti-drip feature is ideal for pharmaceuticals, cosmetics, food industries, and more. These machines handle low-viscosity fluids seamlessly. Easy to operate and maintain, these machines deliver optimal performance, provided you have an air compressor. Trust VEVOR for reliable and accurate cosmetic tube filling and sealing solutions.

Introduction to VEVOR Cosmetic Tube Filling Sealing Machines

High Precision and Functionality

VEVOR machines ensure precise filling. They are equipped with accurate pneumatic systems, making the filling of both high viscosity and low viscosity liquids efficient. It has an anti-drip nozzle that prevents leakage. Adjustable speed and volume meet specific requirements. Use either manual or automatic modes for better control.

Varied Categories for Different Needs

We have various models in our range. Select from filling volumes of 10ml to 1000ml, and choose between single and double-nozzle options. Our machines are made with stainless steel materials. They resist corrosion, rust, or acids. Built for long-lasting durability, our machine is built with high-quality materials like stainless steel.

Suitable for Multiple Scenarios

It’s great to use these machines in cosmetic, food & pharmaceutical industries. They’re perfect for filling creams, oils n lotions. Also, it’ll be ideal for filling honey and other thick materials. Great for small-scale and industrial operations alike.

Choosing the Right VEVOR Cosmetic Tube Filling Sealing Machine

Simple Steps to Select

For small-scale tasks, choose a range of 10ml to 300ml. Higher volumes like 100ml to 1000ml suit larger operations better.

Capacity and Speed Examples

It is important to note that the speed of the machine matches your workflow, especially if you're working on home businesses. Small models fill around 10-20 bottles per minute, ideal for home businesses. Larger models handle up to 80 bottles per minute, suitable for commercial needs. Make sure the device's speed matches with your workflow.

Materials and Environment Suitability

For example, choose stainless steel models for a corrosion-resistant, durable option. Choose based on your product type, whether it’s oil, cream, or thin liquid. Always ensure compatibility with your existing air compressor. VEVOR provides reliable and versatile solutions for all scales of operations.

Why VEVOR Is the Preferred Choice for Cosmetic Tube Filling Sealing Machines

When it comes to choosing a reliable and efficient cosmetic tube filling or sealing machine, VEVOR stands out as the top choice. With high precision and functionality, these machines come with accurate pneumatic systems, ensuring efficient fills of both high and low viscosity liquids. The anti-drip nozzle prevents leakage, making sure your products are filled accurately and without waste.

One of the best things about VEVOR machines is their versatility. With adjustable speed and volume control, you can tailor them to your specific needs. Whether you want manual mode for greater control or automatic mode that allows continuous operation, VEVOR machine meets all your preferences.

Besides being highly functional, these machines are built to last. Made from 304 stainless steel food-grade materials, they resist corrosion, rust and acids or alkali. This durability ensures that your investment in VEVOR equipment continues to deliver high performance over time.

Design: VEVOR machines are built with carefully thought-out details that enhance their efficiency and ease of use. The addition of conveying pipes and non-return valves ensures smooth transfer of liquids without blockages. The soft valve provides an excellent non-return effect, guaranteeing successful filling operations.

Positive Experiences with VEVOR Cosmetic Tube Filling Sealing Machines

Many users have praised VEVOR machines for their reliable performance and ease of use. They appreciate the adjustable speed and volume settings as particularly useful because it lets them customize output to specific project needs. Precision of pneumatic filling system, with an accuracy of 1%, ensures that every fill is consistent and accurate.

One of the biggest benefits that we have mentioned is how durable the machines are. The use of 304 stainless steel materials means that the machine are resistant to corrosion, rust, and other harsh chemical reactions. This makes them ideal for use in various industries, from cosmetics to pharmaceuticals, making sure they maintain their efficiency over time.

Dual control modes—manual and automatic—are extremely helpful for users. Manual mode provides precise control for small batches, while the automatic mode is excellent for larger production runs. This flexibility suits different operational scales, whether for smaller businesses or industrial operations.

In the end, the well-designed details, such as the anti-drip nozzle and advanced air pressure gauge, provide additional security and ease of operation. These features help prevent wastage of materials while providing real-time monitoring of the machine's performance, making the entire process efficient and worry-free.

FAQ

1. What Is the Filling Accuracy of VEVOR Machines?

The VEVOR filling machines boast an accuracy of 1%, ensuring precise and consistent fills.

2. Can These Machines Handle Both High and Low Viscosity Liquids?

Both high and low viscosity liquids are efficiently handled by VEVOR machines.

3. Are There Different Models Available?

The machine is equipped with various filling volumes and speeds, catering to different needs. Yes, VEVOR offers machines with a variety of filling volumes as well as speeds for different purposes.

4. What Materials Are VEVOR Machines Made From?

These machines are made from 304 stainless steel, which makes them resistant to corrosion, rust and acids.

5. Do I Need an Air Compressor to Operate the Machine?

The pneumatic operation of VEVOR filling machines requires an air compressor. Yes, you need an air compressor.

Conclusion

The cosmetic tube filling sealing machines from VEVOR offer a perfect combination of high precision, durability, and versatility. With advanced features such as adjustable speed and volume control, dual control modes, or high-quality stainless steel construction, these machines are designed to meet the diverse needs of various industries. Whether you're in the cosmetics industry, pharmaceuticals, or food industry where your requirements require reliable, efficient, precise fillers solutions, choose VEVOR for an investment that ensures both quality and longevity in your production process.